common rail direct injection (CRDI) , which is a fairly recent design for diesel engines that may also be suitable for passenger automobiles. Though originally intended for commercial use, this design is now in wide use around the globe.

WHY IS IT USED?? IS IT BETTER THAN PREVIOUS ENGINES??

This method is chosen by more and more manufacturers and by individual users because it is fuel efficient as other diesel technologies were. However, CRDI has also provided a tremendous boost in diesel-engine performance. The improvement is mainly due to the common-rail design, which has tubes that connect all the injectors. These injectors are based on the direct-injection concept, as was the case in the past. But the common-rail design was quite a step forward.

PRINCIPLE..

Fuel in the common tube or “rail” is under a set amount of pressure which causes the fuel to be “atomized” or broken down to its smallest particles. This allows the fuel to combine with the air much more efficiently. With proper direct injection, fuel use is highly efficient, with much less waste fuel escaping the system unused.

Modern common rail systems, whilst working on the same principle, are governed by an engine control unit (ECU) which opens each injector electronically rather than mechanically. The first passenger car that used the common rail system was the 1997 model Alfa Romeo 156 1.9 JTD and later on that same year Mercedes-Benz E 320 CDI.

Common rail engines have been used in marine and locomotive applications for some time. The Cooper-Bessemer GN-8 (circa 1942) is an example of a hydraulically operated common rail diesel engine, also known as a modified common rail.

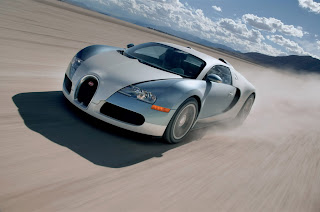

The engines are suitable for all types of road cars with diesel engines, ranging from city cars to large family cars .

Common rail direct fuel injection is a modern variant of direct injection system for diesel engines. It features a high-pressure (1000+ bar) fuel rail feeding individual solenoid valves, as opposed to low-pressure fuel pump feeding Unit Injectors ( pump nozzles) or high-pressure fuel line to mechanical valves controlled by cams on the camshaft. Third generation common rail diesels now feature piezoelectric injectors for even greater accuracy, with fuel pressures up to 180 MPa / 1800 bar, although a new version of Delphis proven diesel common rail system will allow compliance with Euro 6 and US Tier 2 Bin 5 without costly next-generation injection technologies.

Solenoid or piezoelectric valves make possible fine electronic control over the injection time and amount, and the higher pressure that the common rail technology makes available provides better fuel atomisation. In order to lower engine noise, the engine's electronic control unit can inject a small amount of diesel just before the main injection event ("pilot" injection), thus reducing its explosiveness and vibration, as well as optimising injection timing and quantity for variations in fuel quality, cold starting, and so on. Some advanced common rail fuel systems perform as many as five injections per stroke.

Common rail engines require no heating up time, and produce lower engine noise and lower emissions than older systems.

In older diesel engines, a distributor-type injection pump, regulated by the engine, supplies bursts of fuel to injectors which are simply nozzles through which the diesel is sprayed into the engine's combustion chamber. As the fuel is at low pressure and there cannot be precise control of fuel delivery, the spray is relatively coarse and the combustion process is relatively crude and inefficient.

In common rail systems, the distributor injection pump is eliminated. Instead an extremely high pressure pump stores a reservoir of fuel at high pressure up to 2,000 bar (200 MPa) in a "common rail", basically a tube which in turn branches off to computer-controlled injector valves, each of which contains a precision-machined nozzle and a plunger driven by a solenoid. Driven by a computer (which also controls the amount of fuel to the pump), the valves, rather than pump timing, control the precise moment when the fuel injection into the cylinder occurs and also allow the pressure at which the fuel is injected into the cylinders to be increased. As a result, the fuel that is injected atomises easily and burns cleanly, reducing exhaust emissions and increasing efficiency.

TERMS::

A solenoid valve is an electromechanical valve for use with liquid or gas. The valve is controlled by an electric current through a solenoid coil.

A CAM is a small oval rotating or sliding piece which is used to open or close valves in a cylinder of an engine.The timing of the valve depends on the speed of rotation and the length of the TIP. The shaft to which these CAM is attached for rotation is called a CAMSHAFT.

The functioning of a simple Cam is shown below.

Piezoelectricity is the charge which accumulates in certain solid materials in response to applied mechanical strain

The Delphi Unit Pump Diesel Common Rail (UPCR) System is an innovative engine management concept that leverages advanced common rail technology — a proven "green" strategy — for very small diesel engine programs. The system offers manufacturers a cost-effective, robust solution to help them achieve optimal fuel efficiency and meet stringent emissions standards, such as Euro 4.

Key features of the Delphi Diesel UPCR System include fast solenoid diesel injectors and a common rail, a program-tailored engine control module (ECM), robust unit fuel pump with an inlet metering valve, as well as an efficient, low cost fuel filter.

Key features of the Delphi Diesel UPCR System include fast solenoid diesel injectors and a common rail, a program-tailored engine control module (ECM), robust unit fuel pump with an inlet metering valve, as well as an efficient, low cost fuel filter.